Hello Gentlemen,

From what I can understand the step in the exhaust port, at the exit of the port, is to help stop the exhaust gas rushing back into the port after the main exhaust charge been pushed out.

Does the floor of the "D" curve down to the valve seat like the inlet does? It's hard to see in the pictures.

Graeme

Singles Breathing

Moderator: ajleone

-

graeme

- Posts: 1034

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

-

LaceyDucati

- Posts: 606

- Joined: Sun Sep 19, 2010 10:30 pm

- Location: Wales UK

- Contact:

Re: Singles Breathing

As far as I know the reason for the "D" shape is two fold, firstly to improve the radius at the floor of the port, as the sharp turn causes turbulence and adds nothing to the volume of flow. Secondly leaving the port that shape as it meets the exhaust header, acts to form a mismatch reducing reversion and therefore keeping the majority of the exhaust gasses from going back into the engine. That's the theory!

I have tried this and various other variants and it does work. What is clear to me is welding in the material into the exhaust port to improve the turn improves flow, I have also found that raising the port height as much as possible improves flow. Although to achieve this to any real effect, moving the combustion chamber and guide position is the only way to achieve this. Back to the welding torch! I have then also used smaller exhaust valves like 34mm with even better results. For most of my modified heads, I have preferred to improve the exit radius out of the port then slowly return the port to a round shape the size of the valve. Then for instance on my 450 based engines I will step a 36mm port into a 41.5/ 42mm I/D exhaust header pipe. Thus creating probably a similar anti reversion step.

It is true that bigger is not always better so why use such large exhaust valves as my experience says you don't need them? The size of the welded up ports pictured are probably, although relatively well flowing compared with standard port, are probably not making best use of say a 37mm valve. By using smaller exhaust valves this also means you have less of a problem on the overlap with high lift cams allowing use of a larger inlet valve.

so why use such large exhaust valves as my experience says you don't need them? The size of the welded up ports pictured are probably, although relatively well flowing compared with standard port, are probably not making best use of say a 37mm valve. By using smaller exhaust valves this also means you have less of a problem on the overlap with high lift cams allowing use of a larger inlet valve.

I can't really explain further technically, because I, like Eldert, am in the "It works, that good enough for me " camp! Most of what is said here is relative to severely modified heads and to be fair I have obtained reasonable results with fairly standard exhaust ports with a little cleaning up.

I am planning on posting further information and pictures about one of the 450's shortly.

Nigel

I have tried this and various other variants and it does work. What is clear to me is welding in the material into the exhaust port to improve the turn improves flow, I have also found that raising the port height as much as possible improves flow. Although to achieve this to any real effect, moving the combustion chamber and guide position is the only way to achieve this. Back to the welding torch! I have then also used smaller exhaust valves like 34mm with even better results. For most of my modified heads, I have preferred to improve the exit radius out of the port then slowly return the port to a round shape the size of the valve. Then for instance on my 450 based engines I will step a 36mm port into a 41.5/ 42mm I/D exhaust header pipe. Thus creating probably a similar anti reversion step.

It is true that bigger is not always better

I can't really explain further technically, because I, like Eldert, am in the "It works, that good enough for me " camp! Most of what is said here is relative to severely modified heads and to be fair I have obtained reasonable results with fairly standard exhaust ports with a little cleaning up.

I am planning on posting further information and pictures about one of the 450's shortly.

Nigel

Last edited by LaceyDucati on Tue Mar 19, 2013 5:06 pm, edited 3 times in total.

-

LaceyDucati

- Posts: 606

- Joined: Sun Sep 19, 2010 10:30 pm

- Location: Wales UK

- Contact:

Re: Singles Breathing

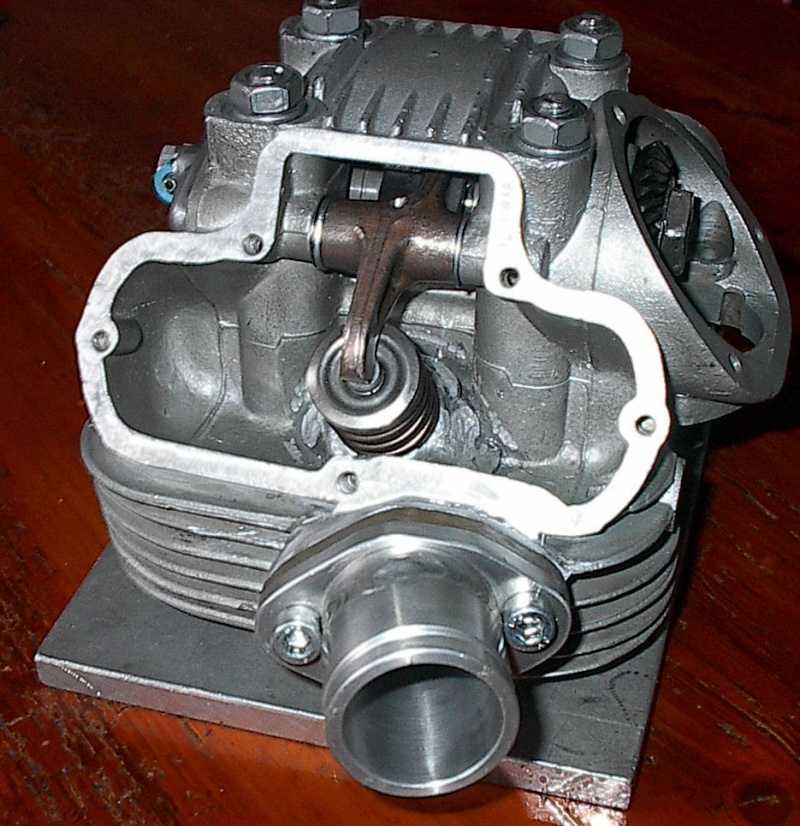

Some information relating to a "480" built some 10 years ago.

Although I have built many race engines over the years, at the time when I was doing most of this work, although I kept very detailed notes, I was not big on photographs as I was late to the digital world. On one of the 450 specials I built there was a rare occasion when I actually took pictures of the work but most of the time I was more interested in the results. This particular engine worked very well and at the moment it still holds the lap record for any Ducati Single for the Isle of Man mountain course. The work on this particular engine was done around ten years ago.

Basic specification:

Bore and stroke of 87mm x 80mm (476cc)

Compression ratio of 11.6:1

Desmo valve gear running with a Vee Two Cam

Valve sizes are 44mm inlet and 36mm exhaust with seat throats of 39.5mm and 32.4mm respectively.

Carb was a 38mm Amal smoothbore.

Maximum power was 47.9 bhp at about 7700rpm (at the back wheel).

Maximum torque being 36.6 ft/lb (torque was fairly flat between 4.5 to 7k)

The inlet port is 36mm at the flange and maintains an area of 36mm diameter throughout the port. The shape of this port changes to a kidney shape to maintain area around the guide. The head was cut and welded to allow this port area and the port is about 42mm wide at the guide, this would normally be well into the fins. The floor of the inlet tract was built up with weld and epoxy to provide a good radius at the floor of the port onto the seat. The heights of the ports have been raised and as can be seen from the pictures, the rocker chambers have been built up and the guides mounted as high as possible. The floor of the exhaust port was built up with weld to improve the radius from the seat to the floor of the port. Exhaust port diameter is 36mm which then steps into a 41.5 mm header pipe.

Unfortunately the view of the actual shape of the ports is distorted in the photos especially the inlet as it is down a long tract with a slight turn in it. For those of you wondering how the carb fits, the engine is not mounted in a standard frame, hence the more central port. The exhaust guide has been cut flush with the port roof which improved flow. This is not normally desirable as you lose contact area with the guide and expose more of the valve to the flame but with the guide mounted higher there was adequate length and contact. Bottom line is that it has never caused a problem in ten years! You will also notice that the combustion chamber has been relieved around the inlet valve as the semi hemi chamber masked the flow into the cylinder. I also spent some time on valve shapes and settled for a large radius underhead shape on the inlet valve which gave the best flow over the whole range of lifts.

The valve angle is standard as altering the valve angle on a Desmo gets complicated unless you are going to 60 degrees using modern rockers. As for the merits of using a 60 degree valve configuration, yes there are advantages in size of valve that can be used, but as the port entry is still in the same place, and you have to turn slightly sharper, with these and other limitations it’s slightly debatable whether you can take advantage of the larger valves with a suitable port. I have re-angled spring valve heads by a degree or so which was plenty to get in the valve sizes I required. Unfortunately I did not take any pictures of the valve spring engines! Needless to say the valve spring engines were just as quick as the Desmo and a lot less hassle. The limiting factor of the 450 Engine is the size of the ports and therefore the valve that can be used, ultimately limiting the revs at which maximum power can be achieved. Consequently with a maximum power below 8000 revs, the Desmo configuration has limited if any use.

I realised at the onset of the project that there was going to be a limitation in ultimate horsepower at higher revs so therefore I decided to stroke the engine for more capacity and planned on getting reasonable top end horsepower with a real good spread of power. With the various other similar engines I built I knew we were at odds with the modern Norton Manx’s but we were pleased to put up some respectable results. A good broad spread of power can make up for a lot on a short circuit and can annoy the hell out a modern Manx rider

I have attached a few pictures taken at the time. It was before I had a digital camera and the pictures were taken on film so apologies for the quality. I don’t feel that I am giving much away in secrets as the results are in the fine detail and it is one hell of a lot of work and if anyone wants to do it – good luck to them.

More photos to follow:

Although I have built many race engines over the years, at the time when I was doing most of this work, although I kept very detailed notes, I was not big on photographs as I was late to the digital world. On one of the 450 specials I built there was a rare occasion when I actually took pictures of the work but most of the time I was more interested in the results. This particular engine worked very well and at the moment it still holds the lap record for any Ducati Single for the Isle of Man mountain course. The work on this particular engine was done around ten years ago.

Basic specification:

Bore and stroke of 87mm x 80mm (476cc)

Compression ratio of 11.6:1

Desmo valve gear running with a Vee Two Cam

Valve sizes are 44mm inlet and 36mm exhaust with seat throats of 39.5mm and 32.4mm respectively.

Carb was a 38mm Amal smoothbore.

Maximum power was 47.9 bhp at about 7700rpm (at the back wheel).

Maximum torque being 36.6 ft/lb (torque was fairly flat between 4.5 to 7k)

The inlet port is 36mm at the flange and maintains an area of 36mm diameter throughout the port. The shape of this port changes to a kidney shape to maintain area around the guide. The head was cut and welded to allow this port area and the port is about 42mm wide at the guide, this would normally be well into the fins. The floor of the inlet tract was built up with weld and epoxy to provide a good radius at the floor of the port onto the seat. The heights of the ports have been raised and as can be seen from the pictures, the rocker chambers have been built up and the guides mounted as high as possible. The floor of the exhaust port was built up with weld to improve the radius from the seat to the floor of the port. Exhaust port diameter is 36mm which then steps into a 41.5 mm header pipe.

Unfortunately the view of the actual shape of the ports is distorted in the photos especially the inlet as it is down a long tract with a slight turn in it. For those of you wondering how the carb fits, the engine is not mounted in a standard frame, hence the more central port. The exhaust guide has been cut flush with the port roof which improved flow. This is not normally desirable as you lose contact area with the guide and expose more of the valve to the flame but with the guide mounted higher there was adequate length and contact. Bottom line is that it has never caused a problem in ten years! You will also notice that the combustion chamber has been relieved around the inlet valve as the semi hemi chamber masked the flow into the cylinder. I also spent some time on valve shapes and settled for a large radius underhead shape on the inlet valve which gave the best flow over the whole range of lifts.

The valve angle is standard as altering the valve angle on a Desmo gets complicated unless you are going to 60 degrees using modern rockers. As for the merits of using a 60 degree valve configuration, yes there are advantages in size of valve that can be used, but as the port entry is still in the same place, and you have to turn slightly sharper, with these and other limitations it’s slightly debatable whether you can take advantage of the larger valves with a suitable port. I have re-angled spring valve heads by a degree or so which was plenty to get in the valve sizes I required. Unfortunately I did not take any pictures of the valve spring engines! Needless to say the valve spring engines were just as quick as the Desmo and a lot less hassle. The limiting factor of the 450 Engine is the size of the ports and therefore the valve that can be used, ultimately limiting the revs at which maximum power can be achieved. Consequently with a maximum power below 8000 revs, the Desmo configuration has limited if any use.

I realised at the onset of the project that there was going to be a limitation in ultimate horsepower at higher revs so therefore I decided to stroke the engine for more capacity and planned on getting reasonable top end horsepower with a real good spread of power. With the various other similar engines I built I knew we were at odds with the modern Norton Manx’s but we were pleased to put up some respectable results. A good broad spread of power can make up for a lot on a short circuit and can annoy the hell out a modern Manx rider

I have attached a few pictures taken at the time. It was before I had a digital camera and the pictures were taken on film so apologies for the quality. I don’t feel that I am giving much away in secrets as the results are in the fine detail and it is one hell of a lot of work and if anyone wants to do it – good luck to them.

More photos to follow:

You do not have the required permissions to view the files attached to this post.

-

LaceyDucati

- Posts: 606

- Joined: Sun Sep 19, 2010 10:30 pm

- Location: Wales UK

- Contact:

Re: Singles Breathing

Pictures - cont'd

You do not have the required permissions to view the files attached to this post.

-

Eldert

- Posts: 824

- Joined: Sun Nov 01, 2009 3:23 pm

- Location: Hazerswoude Rijndijk Netherlands

Re: Singles Breathing

here a picture of the other side of the Mototrans cilinderhead .

i like to put a insulation plate between the head and the manifold . i had the carb fall off one time due to a carb rubber getting hot and it softened up

on my last couple of cilinderheads i moved the manifold studs further apart to . from 52 to 58 mm

Eldert

i like to put a insulation plate between the head and the manifold . i had the carb fall off one time due to a carb rubber getting hot and it softened up

on my last couple of cilinderheads i moved the manifold studs further apart to . from 52 to 58 mm

Eldert

-

double diamond

- Posts: 557

- Joined: Thu Apr 28, 2011 1:20 am

Re: Singles Breathing

Would the Lacey 473 ports have been possible without employing desmo valve actuation? I don’t see adequate room for a valve spring. Desmo valve closure appears to be the only way to raise the valve guide that much. Did the valve spring engines that “were just as quick” employ this raised port design? If so, how were valve springs accommodated with the raised port? I’ve pondered this aspect of desmo valve actuation but never actually observed it employed to such advantage as in the Lacey head. Matt

-

graeme

- Posts: 1034

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

Re: Singles Breathing

Outstanding work, too nice to hide with covers!

Thanks

Thanks

-

LaceyDucati

- Posts: 606

- Joined: Sun Sep 19, 2010 10:30 pm

- Location: Wales UK

- Contact:

Re: Singles Breathing

Hi,

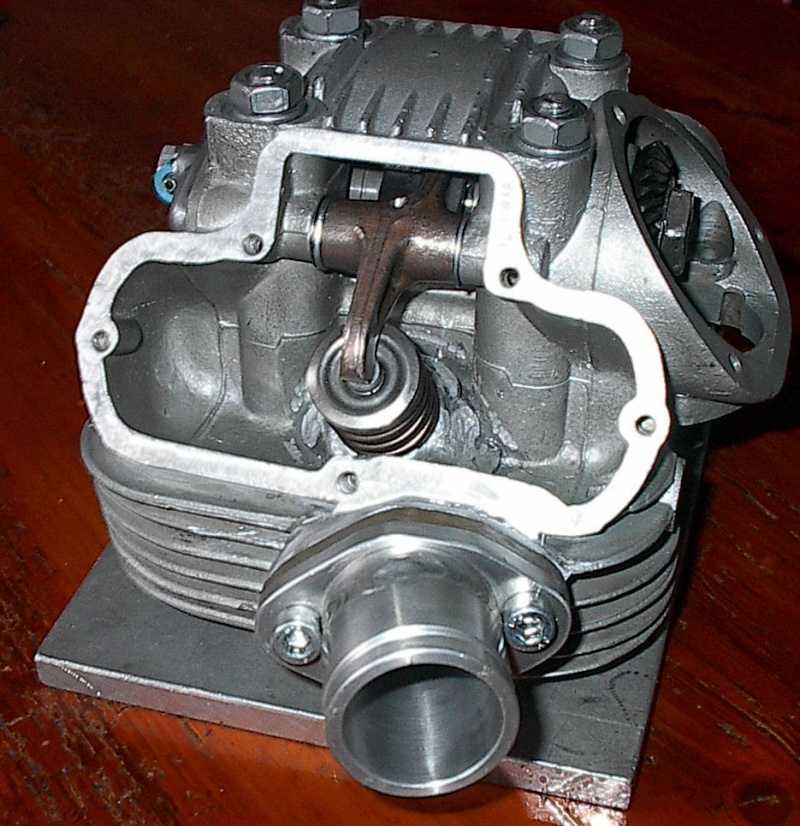

The Desmo closing rocker is actually a hindrance to raising the guide. With a bit of jiggery pokery you can actually get the guide higher on the spring valve engine. My preferred method is to use hairsprings and special carriers allowing the springs to fit in a very tight space. This can be seen in the pictures below. I fortunately have an engine in for work, so I popped the inlet cover off to photograph it. This engine is from the bike owned by Harvey Ellis that Nigel Palmer rides. I built this engine some time ago for Harvey and have maintained it ever since. Harvey is a top guy and true enthusiast, he doesn’t ride himself, but has put a lot into the sport. Anybody in the European Classic racing scene will probably have seen this bike in action. It is 493cc, with a bore and stroke of 88 x 81mm.

It is possible to use coil springs with special deeper tops (just clearing the rocker), but space is a bit tight. Not revving beyond 8000 rpm our 3.8mm hairsprings have no problem keeping everything in check.

Hope this explains the spring valve verses desmo port size question.

Best Wishes Nigel

The Desmo closing rocker is actually a hindrance to raising the guide. With a bit of jiggery pokery you can actually get the guide higher on the spring valve engine. My preferred method is to use hairsprings and special carriers allowing the springs to fit in a very tight space. This can be seen in the pictures below. I fortunately have an engine in for work, so I popped the inlet cover off to photograph it. This engine is from the bike owned by Harvey Ellis that Nigel Palmer rides. I built this engine some time ago for Harvey and have maintained it ever since. Harvey is a top guy and true enthusiast, he doesn’t ride himself, but has put a lot into the sport. Anybody in the European Classic racing scene will probably have seen this bike in action. It is 493cc, with a bore and stroke of 88 x 81mm.

It is possible to use coil springs with special deeper tops (just clearing the rocker), but space is a bit tight. Not revving beyond 8000 rpm our 3.8mm hairsprings have no problem keeping everything in check.

Hope this explains the spring valve verses desmo port size question.

Best Wishes Nigel

You do not have the required permissions to view the files attached to this post.

-

Harvey

- Posts: 108

- Joined: Thu Dec 29, 2011 1:05 am

- Location: Coffs Harbour. Australia.

Re: Singles Breathing

by graeme » Tue Mar 19, 2013 2:06 am

Hello Gentlemen,

From what I can understand the step in the exhaust port, at the exit of the port, is to help stop the exhaust gas rushing back into the port after the main exhaust charge been pushed out.

by LaceyDucati » Tue Mar 19, 2013 12:24 pm

As far as I know the reason for the "D" shape is two fold, firstly to improve the radius at the floor of the port, as the sharp turn causes turbulence and adds nothing to the volume of flow. Secondly leaving the port that shape as it meets the exhaust header, acts to form a mismatch reducing reversion and therefore keeping the majority of the exhaust gasses from going back into the engine. That's the theory!

Yes it is the theory that is leaving me wondering. I have seen this done on Merican V8s, but why it is suppose to prevent “gas reversion” I can’t see.

If they are meaning the actual exhaust gas is being prevented from flowing back into the cylinder towards the end of the exhaust stroke, I don’t see it. When the exhaust valve opens, there is a high-pressure gas front, released into the pipe, to travel down to the end. The inertia of this gas plug develops a low pressure behind it, which reduces the pressure in the pipe and cylinder, to induce the inlet gas to start flowing.

Sure the low pressure can have some gas induced from the exhaust pipe to flow back to the cylinder, but reducing the port area won’t stop the pressure from moving past it. It won’t “reflect or bounce” the gas pressure back.

You can see this happening with an idling 450 by placing a flat card across the end of the Conti to act as a one-way valve, and the idle speed will increase, as all the gas is now pulled through the inlet only.

If they are meaning to prevent the sonic wave from returning to the cylinder, then that won’t stop it, as the wave will just increase in amplitude till it enters the cylinder with no change.

So I am left with the thought that it is the reduction of the port area to increase the gas velocity, that is preventing turbulence, and the change from a straight port to a curve, that suits the direction of flow, that has the port flow increase.

Harvey.

-

LaceyDucati

- Posts: 606

- Joined: Sun Sep 19, 2010 10:30 pm

- Location: Wales UK

- Contact:

Re: Singles Breathing

Harvey, As I said "that's the theory". I'm not saying it's my theory or I totally buy into it or I understand it!

What my observations tell me is, that on a flow bench building up the floor to improve the shape of an exhaust port away from the seat does reduce turbulence and therefore flow. I always base my selection of valves to obtain a good flow and gas speed for the capacity of the engine and my desired revs for peak power. Not on what the factory used or bigger than the factory because "it's a race bike", which seams to be a mis-held belief of many. Therefore I also do not understand (as shown in some of the pictures) why you would strangle a port smaller than a theoretical port size for the given valve, what that's telling me is, it would probably have be even better with a smaller valve gas speed wise. Though if practice says it works............

As for the anti reversion, yes I would agree with you that it won't wholly stop gas going back into the cylinder. But from observation stepping an exhaust port into a larger header doesn’t seem to have any major negative effects on performance. Whereas stepping an exhaust port into a smaller header, sure as hell does! Same goes for putting a large carb or stub with a step onto a smaller inlet port. I would therefore conclude abrupt steps from large to small will have an effect on flow and turbulence. Somewhere in this restricted flow probably lies the increase in mid range or whatever is supposed to happen. I am also led to believe that flow is not uniform throughout the area so this may also have an influence.

You may also note from my pictures, that although I have changed the shape of the port I didn't at the time go for a "D" shaped port myself. My best ever race and dyno proven 350 has a round port at exit, so regardless of the theory it's not essential!

I'm not a theoretical engineer, so I only work from observation and results based on what I can read and take on board, which is based on others theory and results (not normally related to Ducati's). If any theoretical engineers what to explain further, I'm always willing to listen. Listening & observing are a key skill to success, as is being able to make things happen

Best Wishes Nigel

What my observations tell me is, that on a flow bench building up the floor to improve the shape of an exhaust port away from the seat does reduce turbulence and therefore flow. I always base my selection of valves to obtain a good flow and gas speed for the capacity of the engine and my desired revs for peak power. Not on what the factory used or bigger than the factory because "it's a race bike", which seams to be a mis-held belief of many. Therefore I also do not understand (as shown in some of the pictures) why you would strangle a port smaller than a theoretical port size for the given valve, what that's telling me is, it would probably have be even better with a smaller valve gas speed wise. Though if practice says it works............

As for the anti reversion, yes I would agree with you that it won't wholly stop gas going back into the cylinder. But from observation stepping an exhaust port into a larger header doesn’t seem to have any major negative effects on performance. Whereas stepping an exhaust port into a smaller header, sure as hell does! Same goes for putting a large carb or stub with a step onto a smaller inlet port. I would therefore conclude abrupt steps from large to small will have an effect on flow and turbulence. Somewhere in this restricted flow probably lies the increase in mid range or whatever is supposed to happen. I am also led to believe that flow is not uniform throughout the area so this may also have an influence.

You may also note from my pictures, that although I have changed the shape of the port I didn't at the time go for a "D" shaped port myself. My best ever race and dyno proven 350 has a round port at exit, so regardless of the theory it's not essential!

I'm not a theoretical engineer, so I only work from observation and results based on what I can read and take on board, which is based on others theory and results (not normally related to Ducati's). If any theoretical engineers what to explain further, I'm always willing to listen. Listening & observing are a key skill to success, as is being able to make things happen

Best Wishes Nigel

Return to “Ducati Singles Main Discussions (& How to Join)”

Who is online

Users browsing this forum: No registered users and 120 guests