I've seen a picture of the 500 with a 900 rear cylinder and head grafted onto a 450 bottom end.

From memory he was a Dutch fellow, and the picture may have been in the Cathcart book with the 900 Hailwood on the cover. I seem to remember he was the same fellow that did a lot of development on the Pantah engine.

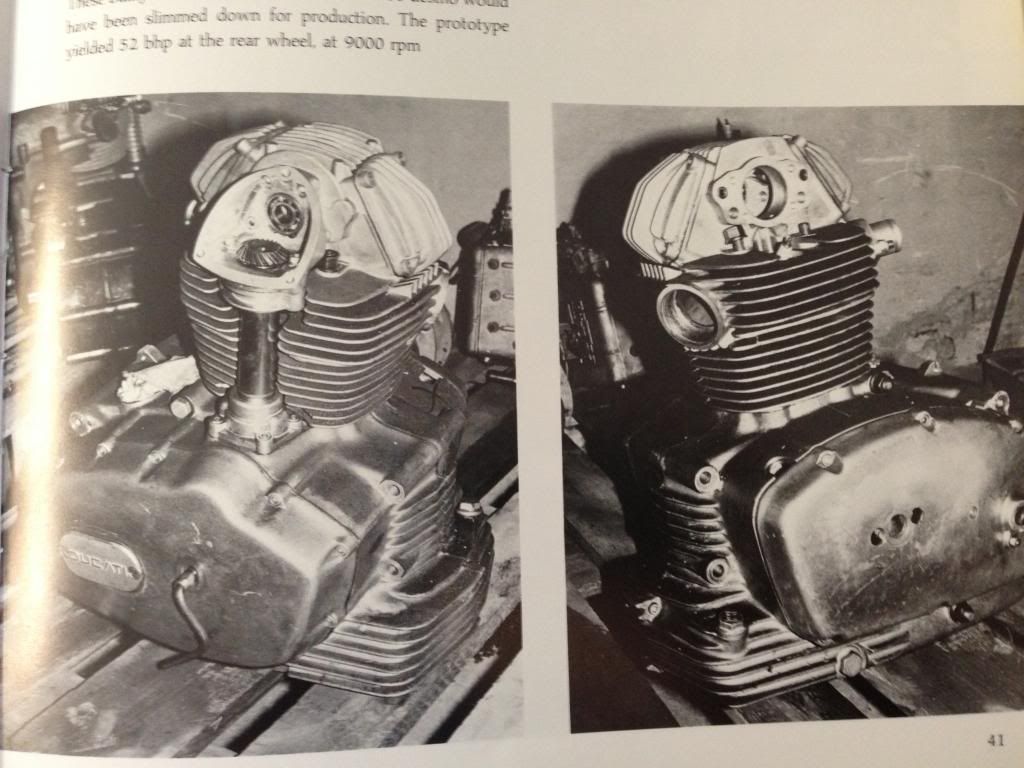

Eng Taglioni also built a proper 500 using a rear cilinder and head from a 900.

And new cases etc.

But the bean counters stopped its production. (Pictures to follow)

Graeme

DESMO Discussions (continued, here) Thread

Moderator: ajleone

-

graeme

- Posts: 1034

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

-

graeme

- Posts: 1034

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

Re: DESMO Discussions (continued, here) Thread

The rest of the very small article says it would have had the side covers slimmed down, and it made 52 rear wheel HP at 9000 rpm.

graeme

-

LaceyDucati

- Posts: 606

- Joined: Sun Sep 19, 2010 10:30 pm

- Location: Wales UK

- Contact:

Re: DESMO Discussions (continued, here) Thread

Hi Graeme

52 HP at the back wheel! I think either they were either very small Italian ponies or the stuff of fantasy. Been tuning and involved in racing Ducati singles for years and if I could get 52 BHP at the back wheel out of a full blown racer I would be happy. Reminds me of a time we got 48 bhp from a customers 480 race single and as a comparison we put a nearly new 900 monster on the dyno back to back. Said claimed 88 BHP came in at 60 BHP! Beware Factory claims.

From my experience with Desmos the problems are not only with the cams but with the machining of the rocker spindle positions and the radius on the rockers. Even using Better ground cams like the Vee two cams I needed to work on the closing rocker radius to achieve "perfectionist" suitable levels of clearance. My opinion is that although you can fettle a particular head (with much engineering and effort) to function well, it is near impossible to manufacture parts to fit with the variations of poor tolerancing and I suspect design in these heads. The best you can do with most road heads is run everything slack enough not to bind and let the springs pick up any short fall (as Bob says!). The factory racers I believe ran 0.15mm (6 thou) closing clearance, relying on cylinder pressure to close the valves. I can add that 6 to 8 thou doesn’t seem to effect performance even with no springs. I aim for one or two thou on a race engine to start with. Though in race use it's only a matter of time before the collets (keepers) or groove get beaten slacker. From our track experience over many years we have built some very fast and reliable Desmo's, but ultimately the spring valve engines are just as fast and reliable.

Best Wishes Nigel

52 HP at the back wheel! I think either they were either very small Italian ponies or the stuff of fantasy. Been tuning and involved in racing Ducati singles for years and if I could get 52 BHP at the back wheel out of a full blown racer I would be happy. Reminds me of a time we got 48 bhp from a customers 480 race single and as a comparison we put a nearly new 900 monster on the dyno back to back. Said claimed 88 BHP came in at 60 BHP! Beware Factory claims.

From my experience with Desmos the problems are not only with the cams but with the machining of the rocker spindle positions and the radius on the rockers. Even using Better ground cams like the Vee two cams I needed to work on the closing rocker radius to achieve "perfectionist" suitable levels of clearance. My opinion is that although you can fettle a particular head (with much engineering and effort) to function well, it is near impossible to manufacture parts to fit with the variations of poor tolerancing and I suspect design in these heads. The best you can do with most road heads is run everything slack enough not to bind and let the springs pick up any short fall (as Bob says!). The factory racers I believe ran 0.15mm (6 thou) closing clearance, relying on cylinder pressure to close the valves. I can add that 6 to 8 thou doesn’t seem to effect performance even with no springs. I aim for one or two thou on a race engine to start with. Though in race use it's only a matter of time before the collets (keepers) or groove get beaten slacker. From our track experience over many years we have built some very fast and reliable Desmo's, but ultimately the spring valve engines are just as fast and reliable.

Best Wishes Nigel

Last edited by LaceyDucati on Tue Mar 05, 2013 10:16 am, edited 1 time in total.

-

Jordan

- Posts: 1501

- Joined: Fri Dec 24, 2010 11:29 am

Re: DESMO Discussions (continued, here) Thread

I photographed this special at a race meeting in Sydney, in the 1980s.

Jordan

Jordan

You do not have the required permissions to view the files attached to this post.

-

Harvey

- Posts: 108

- Joined: Thu Dec 29, 2011 1:05 am

- Location: Coffs Harbour. Australia.

Re: DESMO Discussions (continued, here) Thread

I remember that Forcycle bike, had a Pantah head on it.

Harvey.

-

DewCatTea-Bob

- Posts: 2897

- Joined: Sun Nov 01, 2009 10:53 am

- Location: Near SE side of Lake Michigan

Re: DESMO Discussions (continued, here) Thread

By: LaceyDucati...

" 52 HP at the back wheel!

Been tuning and involved in racing Ducati singles for years and if I could get 52 BHP at the back wheel out of a full blown racer I would be happy. Reminds me of a time we got 48 bhp from a customers 480 race single "

____ Well, I'd say that "48 bhp" is also somewhat overly impressive, (but not unbelievable), so if a 480cc 450-engine (with a fairly well modded regular 450-head) could possibly be coaxed to obtain 1-BHP per 10cc,, then a (near)- 500cc engine with a L-twin cyl.head which can have an intake-port size that's capable of flowing 25 to 35% more air, shouldn't have very much trouble finding merely-just 8% more BHP, (yielding 1-BHP per 9.5cc), which is actually only asking for just 5% more BHP per cc (provided from that added air-flow capability).

__ So bottom-line... since a 480cc engine can really produce 48-BHP, then with such improved intake air-flow, it ought to be quite easy to accept that a 500cc engine (with about 15cc more capacity as well), could possibly achieve the mere 4 additional BHP.

" From my experience with Desmos the problems are not only with the cams but with

the radius on the rockers.

I needed to work on the closing rocker radius to achieve "perfectionist" suitable levels of clearance. "

____ I was unaware that there has also been machining-issues with stock/factory-produced rocker-arms.

" The best you can do with most road heads is run everything slack enough not to bind and let the springs pick up any short fall (as Bob says!). "

____ I believe that it was actually within another thread where I had pointed-out that the factory hadn't bothered with being concerned with closing-lobe perfection because the included valve-springs within their std.production-heads effectively made any such machining-imperfections (even more) unimportant, (and-thus those imperfections which cause 'binding' conflicts with the preferred closing-clearance settings, are not actually an issue that's of any real importance to bother with getting all perfectly straightened-out !).

" The factory racers I believe ran 0.15mm (6 thou) closing clearance, relying on cylinder pressure to close the valves. "

____ Rather, actually,, I believe (that which I first read-of back in a 1967 cycle-mag about Ducati's DESMO-engines without valve-springs), that it's rather the 'momentum' (from the inertial-energy of the closing-lobe's effort to fling the valve closed) which actually shuts the valve up-against it's seat, AND THEN it's the built-up internal-pressure within the cylinder that works to keep the valves held-shut.

So-thus it should be reasonably understandable that FAR-more than "0.15mm" of closing-clearance can still be very workable ! _ In fact, once the valve has been launched-underway (by the closing-lobe's closing-ramp), there's then really no need for ANY set-amount of closing-clearance, (especially for the intake-valve) ! _ And that's why I've declared that the vast-majority of the closing-lobe may as well be nonexistent.

" I can add that 6 to 8 thou doesn’t seem to effect performance even with no springs. "

____ INDEED ! _ As even WELL-OVER a millimeter (.04") would do equally as well in a running-engine, (although kick-starting may be an issue without valve-springs).

" we have built some very fast and reliable Desmo's, but ultimately the spring valve engines are just as fast and reliable. "

____ That's of-course quite so.

__ The only notable advantages of a desmo.setup are... the fact that the lobe-profiles of the opening-cams can get-by with considerably more-radical geometry (for improved cylinder-filling),, and the power-loss due to having-to compress normal-strength valve-springs (at RPMs up-where there'd otherwise be valve-float), is completely eliminated,, (and of-course to a lesser advantages extent), the frictional-loss between the opening cam-lobes & cam-followers is very considerably reduced.

Desmo-DUKEs,

-Bob

" 52 HP at the back wheel!

Been tuning and involved in racing Ducati singles for years and if I could get 52 BHP at the back wheel out of a full blown racer I would be happy. Reminds me of a time we got 48 bhp from a customers 480 race single "

____ Well, I'd say that "48 bhp" is also somewhat overly impressive, (but not unbelievable), so if a 480cc 450-engine (with a fairly well modded regular 450-head) could possibly be coaxed to obtain 1-BHP per 10cc,, then a (near)- 500cc engine with a L-twin cyl.head which can have an intake-port size that's capable of flowing 25 to 35% more air, shouldn't have very much trouble finding merely-just 8% more BHP, (yielding 1-BHP per 9.5cc), which is actually only asking for just 5% more BHP per cc (provided from that added air-flow capability).

__ So bottom-line... since a 480cc engine can really produce 48-BHP, then with such improved intake air-flow, it ought to be quite easy to accept that a 500cc engine (with about 15cc more capacity as well), could possibly achieve the mere 4 additional BHP.

" From my experience with Desmos the problems are not only with the cams but with

the radius on the rockers.

I needed to work on the closing rocker radius to achieve "perfectionist" suitable levels of clearance. "

____ I was unaware that there has also been machining-issues with stock/factory-produced rocker-arms.

" The best you can do with most road heads is run everything slack enough not to bind and let the springs pick up any short fall (as Bob says!). "

____ I believe that it was actually within another thread where I had pointed-out that the factory hadn't bothered with being concerned with closing-lobe perfection because the included valve-springs within their std.production-heads effectively made any such machining-imperfections (even more) unimportant, (and-thus those imperfections which cause 'binding' conflicts with the preferred closing-clearance settings, are not actually an issue that's of any real importance to bother with getting all perfectly straightened-out !).

" The factory racers I believe ran 0.15mm (6 thou) closing clearance, relying on cylinder pressure to close the valves. "

____ Rather, actually,, I believe (that which I first read-of back in a 1967 cycle-mag about Ducati's DESMO-engines without valve-springs), that it's rather the 'momentum' (from the inertial-energy of the closing-lobe's effort to fling the valve closed) which actually shuts the valve up-against it's seat, AND THEN it's the built-up internal-pressure within the cylinder that works to keep the valves held-shut.

So-thus it should be reasonably understandable that FAR-more than "0.15mm" of closing-clearance can still be very workable ! _ In fact, once the valve has been launched-underway (by the closing-lobe's closing-ramp), there's then really no need for ANY set-amount of closing-clearance, (especially for the intake-valve) ! _ And that's why I've declared that the vast-majority of the closing-lobe may as well be nonexistent.

" I can add that 6 to 8 thou doesn’t seem to effect performance even with no springs. "

____ INDEED ! _ As even WELL-OVER a millimeter (.04") would do equally as well in a running-engine, (although kick-starting may be an issue without valve-springs).

" we have built some very fast and reliable Desmo's, but ultimately the spring valve engines are just as fast and reliable. "

____ That's of-course quite so.

__ The only notable advantages of a desmo.setup are... the fact that the lobe-profiles of the opening-cams can get-by with considerably more-radical geometry (for improved cylinder-filling),, and the power-loss due to having-to compress normal-strength valve-springs (at RPMs up-where there'd otherwise be valve-float), is completely eliminated,, (and of-course to a lesser advantages extent), the frictional-loss between the opening cam-lobes & cam-followers is very considerably reduced.

Desmo-DUKEs,

-Bob

PLEASE NOTE... If this-post is not-yet signed-off with '-Bob', then I'm still in the process of completing it,, and if not also included with 'DCT' near bottom as well, then I may edit this post's wording at a later time. - Dct.Bob

-

joe46ho

- Posts: 247

- Joined: Mon Jun 20, 2011 10:45 pm

- Location: Crittenden, KY

- Contact:

Re: DESMO Discussions (continued, here) Thread

Could the problem with the keyway being off, and the intake lobe being too far advanced be due to these cams having not been originally intended for a single at all, but for a v-twin ??

That may seem like a weird question, and I have never owned a V2 cam, but here is why i ask...

About 2 years ago roughly I emailed Brooke Henry about the availability of a camshaft for my dads 350 Desmo which is my brothers now. what prompted me to send the email was seeing a listing for one of the cams on ebay (sold before i could bid on it) and I was curious if more where available... Although I can not find the email i received back, I have a very good memory and I recall getting a response as follows:

"The cam you saw listed was the last one we had available, but if you really need one and are not in a hurry we could make one for you, these are made by modifying/machining a v-twin cam" Bevel or belt i have no idea... The wording might be a little off but i know for certain that i was told this. So could that be the issue ?

One other note, here is a link to 2 current ebay ads for V2 cams from a guy that did a big ducati buyout a while back, he still has these cams and cant sell them, they have been on ebay for a long time...notice what the one package says ?

"60 Degree Single, Bevel to Belt"

http://www.ebay.com/itm/Ducati-Cam-Vee- ... 1a&vxp=mtr

http://www.ebay.com/itm/Ducati-Bevel-Dr ... 230df5cc84

That may seem like a weird question, and I have never owned a V2 cam, but here is why i ask...

About 2 years ago roughly I emailed Brooke Henry about the availability of a camshaft for my dads 350 Desmo which is my brothers now. what prompted me to send the email was seeing a listing for one of the cams on ebay (sold before i could bid on it) and I was curious if more where available... Although I can not find the email i received back, I have a very good memory and I recall getting a response as follows:

"The cam you saw listed was the last one we had available, but if you really need one and are not in a hurry we could make one for you, these are made by modifying/machining a v-twin cam" Bevel or belt i have no idea... The wording might be a little off but i know for certain that i was told this. So could that be the issue ?

One other note, here is a link to 2 current ebay ads for V2 cams from a guy that did a big ducati buyout a while back, he still has these cams and cant sell them, they have been on ebay for a long time...notice what the one package says ?

"60 Degree Single, Bevel to Belt"

http://www.ebay.com/itm/Ducati-Cam-Vee- ... 1a&vxp=mtr

http://www.ebay.com/itm/Ducati-Bevel-Dr ... 230df5cc84

You do not have the required permissions to view the files attached to this post.

Too many projects to list...

12 Ducati singles currently

12 Ducati singles currently

-

Harvey

- Posts: 108

- Joined: Thu Dec 29, 2011 1:05 am

- Location: Coffs Harbour. Australia.

Re: DESMO Discussions (continued, here) Thread

Joe thoes cams are to do the converson of fitting the Pantah head on the single, same as on the Forcycle bike in Jordon's post.

Changing the belt driwe to bevel.

Changing the belt driwe to bevel.

Harvey.

-

joe46ho

- Posts: 247

- Joined: Mon Jun 20, 2011 10:45 pm

- Location: Crittenden, KY

- Contact:

Re: DESMO Discussions (continued, here) Thread

Well in the links i posted there are two different types I only posted the pictures from one link.. but one thing I don't get is this... I thought that conversion was very rare and not "common" by any means so why would they mass produce such an odd cam ? The other thing is this, when I emailed about the cam on eBay from Brooke Henry it was not one of these "conversion cams" so to speak, I specifically asked about the availability of a stock type replacement cam for the 350 desmo, and the reply was to that question (and there reply was as I said "we can make one for you, we just modify/machine a vtwin cam..." So back to that... Does that seem weird or would a desmo twin cams lobe size, orientation , etc actually work on a single ?

Joe

Joe

Too many projects to list...

12 Ducati singles currently

12 Ducati singles currently

-

LaceyDucati

- Posts: 606

- Joined: Sun Sep 19, 2010 10:30 pm

- Location: Wales UK

- Contact:

Re: DESMO Discussions (continued, here) Thread

Bob commented:

"Well, I'd say that "48 bhp" is also somewhat overly impressive, (but not unbelievable), so if a 480cc 450-engine (with a fairly well modded regular 450-head) could possibly be coaxed to obtain 1-BHP per 10cc,, then a (near)- 500cc engine with a L-twin cyl.head which can have an intake-port size that's capable of flowing 25 to 35% more air, shouldn't have very much trouble finding merely-just 8% more BHP, (yielding 1-BHP per 9.5cc), which is actually only asking for just 5% more BHP per cc (provided from that added air-flow capability).

__ So bottom-line... since a 480cc engine can really produce 48-BHP, then with such improved intake air-flow, it ought to be quite easy to accept that a 500cc engine (with about 15cc more capacity as well), could possibly achieve the mere 4 additional BHP."

- 48 bhp is from a severely modified head with a port higher and larger than a standard Bevel Twin head. Its also running a race cam 12:1 compression 38mm Carb and open large bore pipe and Mega. The factory engine is supposed to be a road bike development and one would assume it would be far short of race spec. The bevel twin heads dont flow very well and if you can find me a bevel twin doing 104bhp + at the back wheel I would be very interested! The problem is with the bevel twin head is there is little room in the casting, the floors of the ports are flat with an appalling turn on the valve seat, worse than a standard single head which is hard to believe. With the 450's the problem is to achieve this sort of horsepower you have stretched everything within an inch of its life, then adding 5% more to something already at capacity isn't as simple as it may sound. I am sure Eldert could confirm this for you!

"____ I was unaware that there has also been machining-issues with stock/factory-produced rocker-arms."

If you swap rocker arms around it will be noted that these variations in clearance change from one arm to another to some extent identifying inaccuracies. I chose to slightly alter the radius and position of the radius on the closing rocker arm to eliminate the errors. Using Vee Two cams without any modification I managed very consistent clearances. It was clear to me in my investigation that with a slight change of the follower things could be improved somewhat. The opening rockers were all reprofiled but to the "standard" radius but consistently the same. As a further note to do with the rocker spindle positions for anyone so inclined to fiddle around with these things. Get four pieces of 8mm ground silver steel (ensuring they are straight) put them in the 4 rocker spindle holes and then put the head up to the light and look at the spindles, ummm you now have the answer why rockers run up one edge of the rocker face. If you really want to worry yourself, start measuring the centre positions of the holes. All these inaccuracies explain why sometimes you good ones and sometimes you get bad ones!

" INDEED ! _ As even WELL-OVER a millimeter (.04") would do equally as well in a running-engine, (although kick-starting may be an issue without valve-springs). "

- I would not run a road bike without springs but adding the bevel twin assister springs will overcome those problems.

"____ Rather, actually,, I believe (that which I first read-of back in a 1967 cycle-mag about Ducati's DESMO-engines without valve-springs), that it's rather the 'momentum' (from the inertial-energy of the closing-lobe's effort to fling the valve closed) which actually shuts the valve up-against it's seat, AND THEN it's the built-up internal-pressure within the cylinder that works to keep the valves held-shut.

So-thus it should be reasonably understandable that FAR-more than "0.15mm" of closing-clearance can still be very workable ! _ In fact, once the valve has been launched-underway (by the closing-lobe's closing-ramp), there's then really no need for ANY set-amount of closing-clearance, (especially for the intake-valve) ! _ And that's why I've declared that the vast-majority of the closing-lobe may as well be nonexistent. "

- Obviously I agree with you here, I was using the term "shut" meaning sealing. Just trying to make simple statements without ending up writing war and peace.

"____ That's of-course quite so.

__ The only notable advantages of a desmo.setup are... the fact that the lobe-profiles of the opening-cams can get-by with considerably more-radical geometry (for improved cylinder-filling),, and the power-loss due to having-to compress normal-strength valve-springs (at RPMs up-where there'd otherwise be valve-float), is completely eliminated,, (and of-course to a lesser advantages extent), the frictional-loss between the opening cam-lobes & cam-followers is very considerably reduced. "

Good theory but I have never come across a Desmo cam profile from either a bevel single or twin which cannot be run with a spring valve engine running suitable springs.

Nigel

"Well, I'd say that "48 bhp" is also somewhat overly impressive, (but not unbelievable), so if a 480cc 450-engine (with a fairly well modded regular 450-head) could possibly be coaxed to obtain 1-BHP per 10cc,, then a (near)- 500cc engine with a L-twin cyl.head which can have an intake-port size that's capable of flowing 25 to 35% more air, shouldn't have very much trouble finding merely-just 8% more BHP, (yielding 1-BHP per 9.5cc), which is actually only asking for just 5% more BHP per cc (provided from that added air-flow capability).

__ So bottom-line... since a 480cc engine can really produce 48-BHP, then with such improved intake air-flow, it ought to be quite easy to accept that a 500cc engine (with about 15cc more capacity as well), could possibly achieve the mere 4 additional BHP."

- 48 bhp is from a severely modified head with a port higher and larger than a standard Bevel Twin head. Its also running a race cam 12:1 compression 38mm Carb and open large bore pipe and Mega. The factory engine is supposed to be a road bike development and one would assume it would be far short of race spec. The bevel twin heads dont flow very well and if you can find me a bevel twin doing 104bhp + at the back wheel I would be very interested! The problem is with the bevel twin head is there is little room in the casting, the floors of the ports are flat with an appalling turn on the valve seat, worse than a standard single head which is hard to believe. With the 450's the problem is to achieve this sort of horsepower you have stretched everything within an inch of its life, then adding 5% more to something already at capacity isn't as simple as it may sound. I am sure Eldert could confirm this for you!

"____ I was unaware that there has also been machining-issues with stock/factory-produced rocker-arms."

If you swap rocker arms around it will be noted that these variations in clearance change from one arm to another to some extent identifying inaccuracies. I chose to slightly alter the radius and position of the radius on the closing rocker arm to eliminate the errors. Using Vee Two cams without any modification I managed very consistent clearances. It was clear to me in my investigation that with a slight change of the follower things could be improved somewhat. The opening rockers were all reprofiled but to the "standard" radius but consistently the same. As a further note to do with the rocker spindle positions for anyone so inclined to fiddle around with these things. Get four pieces of 8mm ground silver steel (ensuring they are straight) put them in the 4 rocker spindle holes and then put the head up to the light and look at the spindles, ummm you now have the answer why rockers run up one edge of the rocker face. If you really want to worry yourself, start measuring the centre positions of the holes. All these inaccuracies explain why sometimes you good ones and sometimes you get bad ones!

" INDEED ! _ As even WELL-OVER a millimeter (.04") would do equally as well in a running-engine, (although kick-starting may be an issue without valve-springs). "

- I would not run a road bike without springs but adding the bevel twin assister springs will overcome those problems.

"____ Rather, actually,, I believe (that which I first read-of back in a 1967 cycle-mag about Ducati's DESMO-engines without valve-springs), that it's rather the 'momentum' (from the inertial-energy of the closing-lobe's effort to fling the valve closed) which actually shuts the valve up-against it's seat, AND THEN it's the built-up internal-pressure within the cylinder that works to keep the valves held-shut.

So-thus it should be reasonably understandable that FAR-more than "0.15mm" of closing-clearance can still be very workable ! _ In fact, once the valve has been launched-underway (by the closing-lobe's closing-ramp), there's then really no need for ANY set-amount of closing-clearance, (especially for the intake-valve) ! _ And that's why I've declared that the vast-majority of the closing-lobe may as well be nonexistent. "

- Obviously I agree with you here, I was using the term "shut" meaning sealing. Just trying to make simple statements without ending up writing war and peace.

"____ That's of-course quite so.

__ The only notable advantages of a desmo.setup are... the fact that the lobe-profiles of the opening-cams can get-by with considerably more-radical geometry (for improved cylinder-filling),, and the power-loss due to having-to compress normal-strength valve-springs (at RPMs up-where there'd otherwise be valve-float), is completely eliminated,, (and of-course to a lesser advantages extent), the frictional-loss between the opening cam-lobes & cam-followers is very considerably reduced. "

Good theory but I have never come across a Desmo cam profile from either a bevel single or twin which cannot be run with a spring valve engine running suitable springs.

Nigel

Return to “Ducati Singles Main Discussions (& How to Join)”

Who is online

Users browsing this forum: No registered users and 88 guests