Now Bob, why wouldn't I take your advice? Not that I plunge in head first if someone tells me to do something. But I tend to take all advice "under advisement" and continue to do research and learn, which should eventually prove some advice to be valuable and other to be not so valuable.

Actually, you and I tend to think along the same lines. I want a very streetable machine as it will never see the race track except for maybe a spirited parade lap now and then.

The ugly cam is from an engine that was found in the dump. My guess, after pulling this engine apart as far as I needed to go before I realized it was an anchor, is that it ended up in the dump because somebody else realized this long ago. Probaby a bike that never saw any maintenance, was run low on oil and flogged continuously. Somebody had taken it apart and then put it back together from what I found inside.

The other cam, which is actually pretty good, was sitting on the shelf in my friend's trailer of parts. No telling what its life was before it arrived on his shelf. For years he bought Ducati single parts when they were dirt cheap at swap meets. History rarely comes with used parts at meets.

That all said, today was play with the cams day. I downloaded Jim Panetta's cam info from the Ducatimecchanica site. There is no vestige of paint markings on either of my cams, so measuring them was required to determine their grind and application.

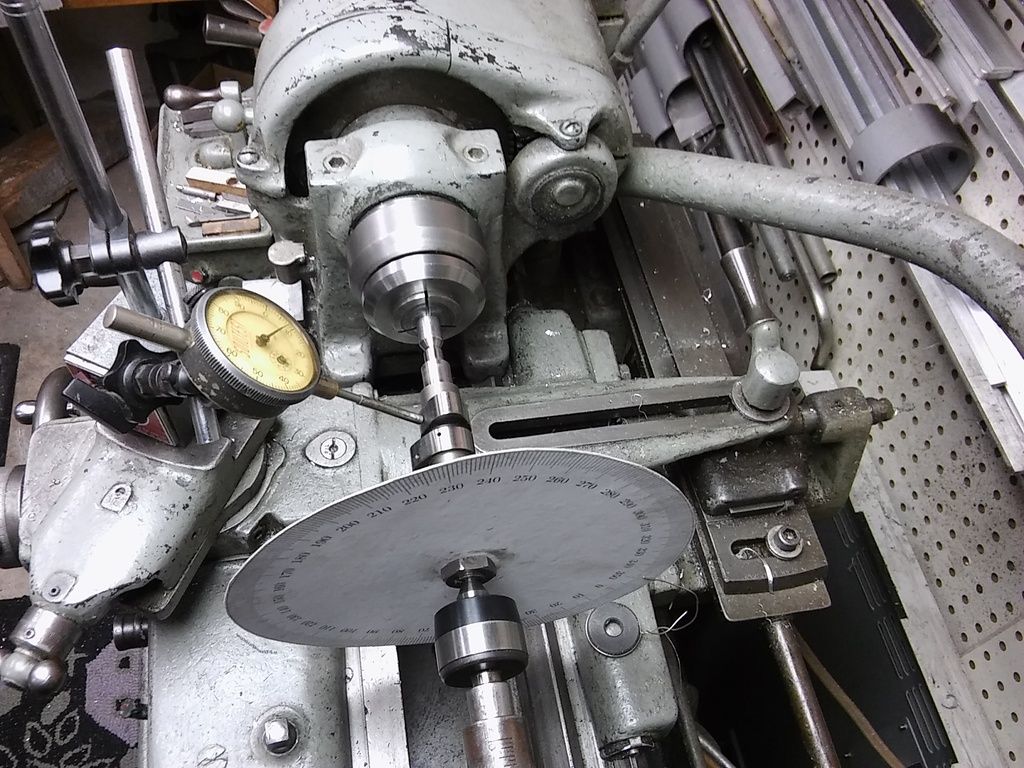

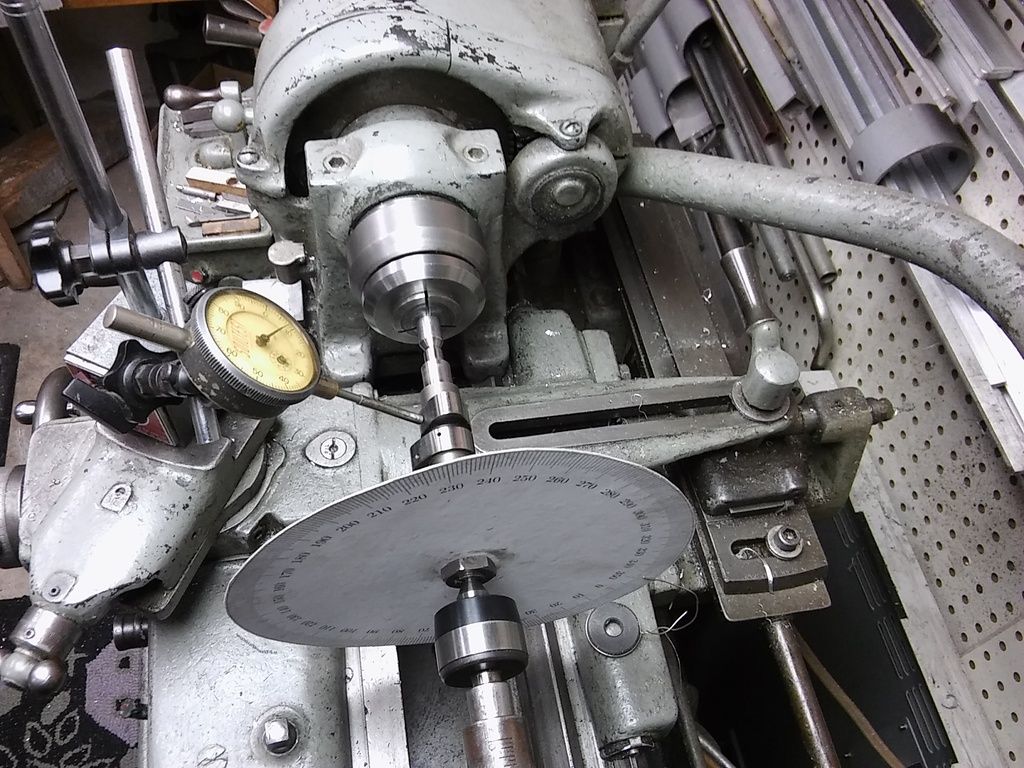

Here's the set-up I used. Degree wheel was simply a printout from my computer and glued to a piece of cardboard. I prefer these over a metal wheel because I can write on them with a pencil and just print out another if the current one is too fugly to use any longer.

The degree pointer is a piece of safety wire on that round magnet stuck to the carriage. Cam is mounted on centers. Lathe spindle stays stationary.

Both my cams are Monza cams. The good cam measures max lift in line with what is in Jim's cam info. 20/70 intake, 50/30 exhaust. Jim measured max lift on both lobes between 7.8mm and 7.6mm for five violet (250 Monza) cams. My good cam measured 7.79 intake and 7.63 exhaust. My base circle was a bit larger at 25.05mm on the intake and in the middle of his measurements at 24.69mm exhaust. Jim's measurements ranged from 24.35mm to 24.9mm.

I measured the timing two ways. First I assumed that the opening point was perfect and set my degree wheel there. I then went around until I hit the closing spot. The other way was to determine the number of degrees for the max lift on a perfect cam. I then set the degree wheel for that point at max lift and went back and read the open and close points. In both cases I was within a degree of perfect. Tolerance per the manual is +/- 5 deg.

My bad cam was actually not that bad from a measurement POV. The max lift was down from spec at 7.24mm intake and 7.33mm exhaust. And there is a nasty dip in the opening ramp on the intake. But if it were my only cam, it would be worthwhile to either have it reground or repaired unless it turned out to cost more than a new cam, if you can find a new stock cam. I need to go back and look at the vendors again.

I'm going to pay special attention to the rocker shimming at assembly time. Need to assure the rocker is centered on the cam lobes. Although it might be dynamics while running that pushes the rocker against the spring and misaligns it.

That's it for cams. Looks like I have a good cam for the engine build.

regards,

Rob