Not a good weekend... 350 NC dis-assembly

Posted: Sun Mar 15, 2015 6:12 pm

Folks,

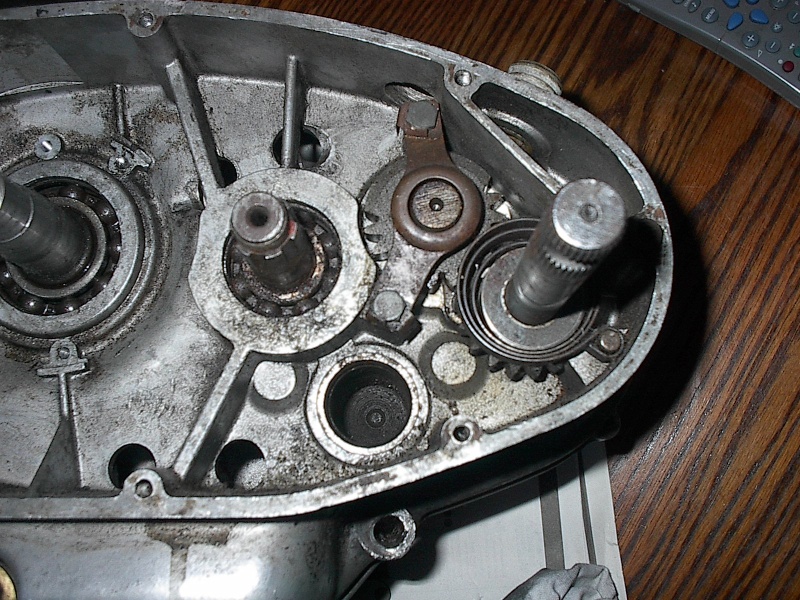

I completed the dis-assembly of the engine on my '65 Sebring this weekend and uncovered a number of issues, so I'm looking for some advice. It became evident during the dis-assembly that the engine had been apart a number of times, with various degrees of abuse evident. On to the good stuff...

1) the boss that supports the kick starter is broken, in the usual manner. I will have the boss TIG welded up, and the bore re-drilled. The problem is that the brass bushing is severely damaged. Does anybody know of a source for this, and potentially other bushings within the engine?

2) the piston pin was seized within the piston (not on the rod), and the piston skirt was broken. We tried everything we could to remove the pin, with no success. I will now try to cut the piston off the rod. The original piston is marked with Borgo 76-65162/2. I would like to replace with an original piston, but I'll also consider a new piston. Any thoughts?

3) the nut holding the bevel gear onto the crank was seized onto the crank. Heating, cooling and copious lubricating oils did nothing to to ease the nut. The thread is now damaged... so what to do? I can a) replace the crank or b) rebuild the surface and re-cut the threads or c) machine the OD down to the same diameter as the un-threaded part, then cut a smaller thread between the end of the shaft and the bevel gear. If I went with option c) I could then use a thicker nut which would have sufficient threads to provide the same force onto the bevel gear. Heck I could even consider a castlelated nut and drill through the shaft. Thoughts?

Thanks in advance,

Mike

I completed the dis-assembly of the engine on my '65 Sebring this weekend and uncovered a number of issues, so I'm looking for some advice. It became evident during the dis-assembly that the engine had been apart a number of times, with various degrees of abuse evident. On to the good stuff...

1) the boss that supports the kick starter is broken, in the usual manner. I will have the boss TIG welded up, and the bore re-drilled. The problem is that the brass bushing is severely damaged. Does anybody know of a source for this, and potentially other bushings within the engine?

2) the piston pin was seized within the piston (not on the rod), and the piston skirt was broken. We tried everything we could to remove the pin, with no success. I will now try to cut the piston off the rod. The original piston is marked with Borgo 76-65162/2. I would like to replace with an original piston, but I'll also consider a new piston. Any thoughts?

3) the nut holding the bevel gear onto the crank was seized onto the crank. Heating, cooling and copious lubricating oils did nothing to to ease the nut. The thread is now damaged... so what to do? I can a) replace the crank or b) rebuild the surface and re-cut the threads or c) machine the OD down to the same diameter as the un-threaded part, then cut a smaller thread between the end of the shaft and the bevel gear. If I went with option c) I could then use a thicker nut which would have sufficient threads to provide the same force onto the bevel gear. Heck I could even consider a castlelated nut and drill through the shaft. Thoughts?

Thanks in advance,

Mike