Folks,

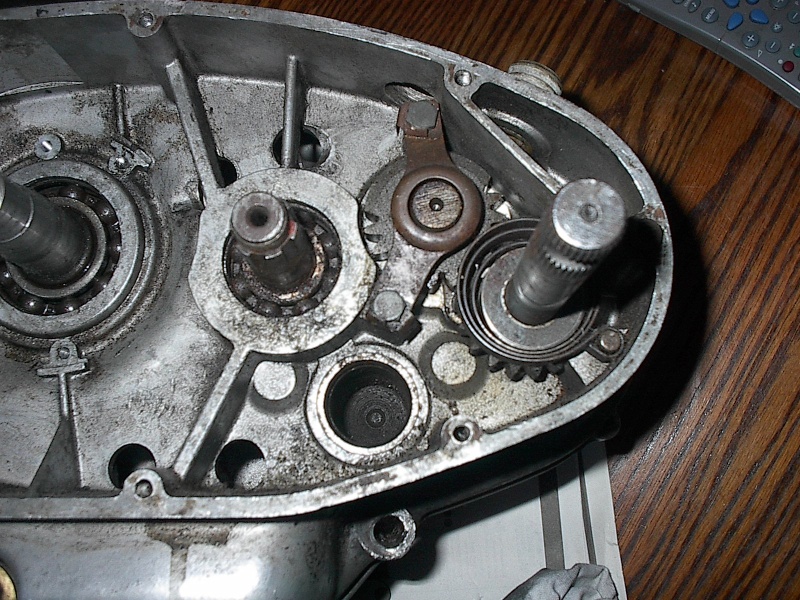

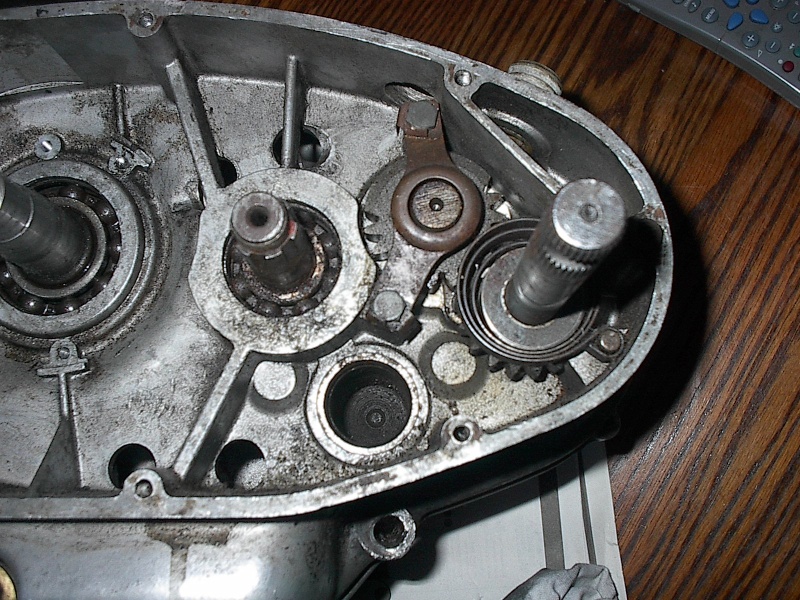

I completed the dis-assembly of the engine on my '65 Sebring this weekend and uncovered a number of issues, so I'm looking for some advice. It became evident during the dis-assembly that the engine had been apart a number of times, with various degrees of abuse evident. On to the good stuff...

1) the boss that supports the kick starter is broken, in the usual manner. I will have the boss TIG welded up, and the bore re-drilled. The problem is that the brass bushing is severely damaged. Does anybody know of a source for this, and potentially other bushings within the engine?

2) the piston pin was seized within the piston (not on the rod), and the piston skirt was broken. We tried everything we could to remove the pin, with no success. I will now try to cut the piston off the rod. The original piston is marked with Borgo 76-65162/2. I would like to replace with an original piston, but I'll also consider a new piston. Any thoughts?

3) the nut holding the bevel gear onto the crank was seized onto the crank. Heating, cooling and copious lubricating oils did nothing to to ease the nut. The thread is now damaged... so what to do? I can a) replace the crank or b) rebuild the surface and re-cut the threads or c) machine the OD down to the same diameter as the un-threaded part, then cut a smaller thread between the end of the shaft and the bevel gear. If I went with option c) I could then use a thicker nut which would have sufficient threads to provide the same force onto the bevel gear. Heck I could even consider a castlelated nut and drill through the shaft. Thoughts?

Thanks in advance,

Mike

Not a good weekend... 350 NC dis-assembly

Moderator: ajleone

-

SebringMike

- Posts: 37

- Joined: Sun Nov 02, 2014 5:43 pm

Not a good weekend... 350 NC dis-assembly

You do not have the required permissions to view the files attached to this post.

2004 BMW R1100S, 1986 Kawasaki ZX750R, 1982 Piaggio PX125E, 1979 Ducati Regolarita

1971 Kawasaki H1A, 1970 Yamaha XS1, 1970 Yamaha R5, 1969 Honda CB750K0

1965 Ducati Sebring

1971 Kawasaki H1A, 1970 Yamaha XS1, 1970 Yamaha R5, 1969 Honda CB750K0

1965 Ducati Sebring

-

DewCatTea-Bob

- Posts: 2897

- Joined: Sun Nov 01, 2009 10:53 am

- Location: Near SE side of Lake Michigan

Re: Not a good weekend... 350 NC dis-assembly

[quote= SebringMike ...

" the boss that supports the kick starter is broken, in the usual manner. I will have the boss TIG welded up, and the bore re-drilled. The problem is that the brass bushing is severely damaged. "

____ I see that the ks.shaft's case-boss is indeed pretty-much broken in the usual manner (if not even slightly worse). ...

Of all the instances which I've also had to deal-with,, instead of going-through all the trouble that you've intended to get done, I'd rather just lathe my-own special replacement-bushing. _ It's 'specially' formed so that it not-only has the usual dimensions of the stock-bushing, but also includes an added built-in rim-lip which would pretty-much take-up the same space normally occupied by the stock 'thrust-washer' (which was sometimes replaced by a much-thinner version, [depending on the rim-lip's particular lathed dimensions]).

I much recommend this bushing-modification regardless of whether you still go-through with your intended weld & re-bore procedure,, as the included built-in rim-lip incorporated into the bushing, provides significant additional strength to that stressed end of the bushing !

I believe I may still have most of the practice bushing-rejects I did on a lathe that had turned-out with less than perfect fitment dimensions. _ If you'd like the exact dimensions of the modified-bushing for lathing your own special-bushings,, then please ask, and I'll then look them up for you.

2) the piston pin was seized within the piston

We tried everything we could to remove the pin, with no success. "

____ Did you ever try setting a sealed plastic-bag filled with ice-water left laying over & around the piston until the ice is almost melted, (to get the pin fully cooled-down),, and then remove the bag and next immediately pour boiling-oil/min.spirits over the piston, (just before going-ahead with the use of a piston-pin puller-tool) ? _ That shocking process should do the job !

" I would like to replace with an original piston, but I'll also consider a new piston. Any thoughts? "

____ If you rather happen to find a w-c.350-piston, then be prepared to have-to cut-down it's skirt-length (to clear the flywheels [due-to the 10mm.shorter n-c.con-rod]) !

" the nut holding the bevel gear onto the crank was seized onto the crank. Heating, cooling and copious lubricating oils did nothing to to ease the nut. The thread is now damaged... "

____ That's a common happenstance due-to many non-Ducati mechanics not realizing that those treads are LEFT-hand type !

Usually they strip-off the nut, and leave the shaft-threads somewhat reusable by cleaning-up what's left of them and rather installing a machine-shop made replacement left-hand nut with deeper threads (than the stock nut). - Usually works well enough.

Hopeful-Cheers,

-Bob

" the boss that supports the kick starter is broken, in the usual manner. I will have the boss TIG welded up, and the bore re-drilled. The problem is that the brass bushing is severely damaged. "

____ I see that the ks.shaft's case-boss is indeed pretty-much broken in the usual manner (if not even slightly worse). ...

Of all the instances which I've also had to deal-with,, instead of going-through all the trouble that you've intended to get done, I'd rather just lathe my-own special replacement-bushing. _ It's 'specially' formed so that it not-only has the usual dimensions of the stock-bushing, but also includes an added built-in rim-lip which would pretty-much take-up the same space normally occupied by the stock 'thrust-washer' (which was sometimes replaced by a much-thinner version, [depending on the rim-lip's particular lathed dimensions]).

I much recommend this bushing-modification regardless of whether you still go-through with your intended weld & re-bore procedure,, as the included built-in rim-lip incorporated into the bushing, provides significant additional strength to that stressed end of the bushing !

I believe I may still have most of the practice bushing-rejects I did on a lathe that had turned-out with less than perfect fitment dimensions. _ If you'd like the exact dimensions of the modified-bushing for lathing your own special-bushings,, then please ask, and I'll then look them up for you.

2) the piston pin was seized within the piston

We tried everything we could to remove the pin, with no success. "

____ Did you ever try setting a sealed plastic-bag filled with ice-water left laying over & around the piston until the ice is almost melted, (to get the pin fully cooled-down),, and then remove the bag and next immediately pour boiling-oil/min.spirits over the piston, (just before going-ahead with the use of a piston-pin puller-tool) ? _ That shocking process should do the job !

" I would like to replace with an original piston, but I'll also consider a new piston. Any thoughts? "

____ If you rather happen to find a w-c.350-piston, then be prepared to have-to cut-down it's skirt-length (to clear the flywheels [due-to the 10mm.shorter n-c.con-rod]) !

" the nut holding the bevel gear onto the crank was seized onto the crank. Heating, cooling and copious lubricating oils did nothing to to ease the nut. The thread is now damaged... "

____ That's a common happenstance due-to many non-Ducati mechanics not realizing that those treads are LEFT-hand type !

Usually they strip-off the nut, and leave the shaft-threads somewhat reusable by cleaning-up what's left of them and rather installing a machine-shop made replacement left-hand nut with deeper threads (than the stock nut). - Usually works well enough.

Hopeful-Cheers,

-Bob

You do not have the required permissions to view the files attached to this post.

PLEASE NOTE... If this-post is not-yet signed-off with '-Bob', then I'm still in the process of completing it,, and if not also included with 'DCT' near bottom as well, then I may edit this post's wording at a later time. - Dct.Bob

-

SebringMike

- Posts: 37

- Joined: Sun Nov 02, 2014 5:43 pm

Re: Not a good weekend... 350 NC dis-assembly

Bob,

Thanks for the insightful answers to my questions/comments.

I would be grateful if you could supply dimensions for the bushing. This does indeed sound like a good fix, coupled with a rebuild of the boss.

Re the piston pin... nope didn't try ice/hot water. I'll add that one to the "toolbox".

Will keep my eyes open for a WC 350 piston, if I'm unable to find a NC piston.

I'm also considering purchasing a new piston... any thoughts on suppliers... good experiences with specific brands?

Re the bevel gear. I will have the the thread cleaned up, and the bevel gear ground down. Another great suggestion.

Thanks for the continued support.

Mike

Thanks for the insightful answers to my questions/comments.

I would be grateful if you could supply dimensions for the bushing. This does indeed sound like a good fix, coupled with a rebuild of the boss.

Re the piston pin... nope didn't try ice/hot water. I'll add that one to the "toolbox".

Will keep my eyes open for a WC 350 piston, if I'm unable to find a NC piston.

I'm also considering purchasing a new piston... any thoughts on suppliers... good experiences with specific brands?

Re the bevel gear. I will have the the thread cleaned up, and the bevel gear ground down. Another great suggestion.

Thanks for the continued support.

Mike

2004 BMW R1100S, 1986 Kawasaki ZX750R, 1982 Piaggio PX125E, 1979 Ducati Regolarita

1971 Kawasaki H1A, 1970 Yamaha XS1, 1970 Yamaha R5, 1969 Honda CB750K0

1965 Ducati Sebring

1971 Kawasaki H1A, 1970 Yamaha XS1, 1970 Yamaha R5, 1969 Honda CB750K0

1965 Ducati Sebring

-

DewCatTea-Bob

- Posts: 2897

- Joined: Sun Nov 01, 2009 10:53 am

- Location: Near SE side of Lake Michigan

Re: Not a good weekend... 350 NC dis-assembly

[quote= SebringMike ...

" I would be grateful if you could supply dimensions for the bushing. "

____ I've been delaying my response whilst trying to find anything I've had related to this, but have-to give-up further searching. _ Still, it shouldn't be any problem to figure-out the dimensions...

While my actual lathe-work was always done in thousandths of an inch, (of which the particular dimension-figures are no-longer memorized by me),, I'm now assuming that the metric-dimensions of the stock bushing we are in reference-to, is either 16-id x 20-od x 12mm, or 15-id x 18-od x 10mm. _ However my nearly 4-decade old memory seems to recall that bushing as rather being 15-id x 20-od x 10mm, so I really need a mind-refresher to get all the actual details to come-back to me (without finding any of my old related stuff). _ So if you could confirm the actual size of your (busted)/original bushing as well as the dimensions of the thrust-washer, that would then allow me to figure-out the actual required dimensions of the special-bushing.

__ Anyhow,, my special-bushing had the same general dimensions as stock, except for the extra added-on dimensions of the included 'rim-lip'.

The first special-bushing examples I made in the late-60s had their rim-lip dimensions done with thickness & OD sizes that were slightly smaller than that of the stock thrust-washer (which was intended to be replaced with a thin bevel-shim -[either a .1mm #0400.29.124 or a .2mm #0400.29.125]).

However after having come-across more badly busted case-bosses (like yours) by the mid-70s,, my later bushing-examples were rather made with the reasoning that the function of a thrust-washer wasn't really needed, and-so their rim-lip dimensions were increased to the full-thickness of the stock thrust-washer along-with a slightly larger OD.

Which of those special-bushing versions you pick to choose for your project, will depend on whether you bother to rebuild your busted case-boss or not.

" coupled with a rebuild of the boss. "

____ If you choose to make your replacement bushing with the larger/thrust-washerless rim-lip spec/version, then rebuilding of the boss ought-not really be required. _ Since the normal kick-starting process doesn't overstress that busted area of the case-boss, (as it had gotten busted rather by a severe 'kick-back').

__ After having installed any special-bushing, I've never afterward happened to have ever found one busted or even cracked,, but that's not to imply such is impossible, (as I did once later find one of my early-versions slightly ovalized). _ So you may wish to consider making your modified-bushing out-of something stronger than a brass-alloy, (if you don't rebuild your case-boss).

I once made one special-bushing example out-of a rather strong alloy of steel, and-but never installed it for over a decade after,, but it finally got installed into a Sebring-motor with an extra-damaged boss like yours, (however I've never seen it again).

" Will keep my eyes open for a WC 350 piston, if I'm unable to find a NC piston.

I'm also considering purchasing a new piston... any thoughts on suppliers... "

____ If your con.rod bushing also shows need for attention, it could be reamed-out about 41-thousandths to accept the pin of a BSA-441 piston, which I-think come with a minimum bore-size of 3.105" -(about 78.9mm), which takes the 350-cyl.sleeve out to near it's max.bore-size.

(Just mentioning this in-case you can't source a Ducati-piston any cheaper and have both of the two problems to solve.)

__ UPDATE - While checking to see if the BSA-pistons are still commonly listed on eBay, I then found that a used 350-piston was also listed... http://www.ebay.com/itm/AE-Piston-for-D ... 50&vxp=mtr

You might-not find another std.sized good one available for under a 100-bucks again.

" I will have the the thread cleaned up, and the bevel gear ground down. "

____ After having the stripped/mashed-over metal carefully cleaned-out from the valleys of the original thread-grooving,, then a new L.hand-nut ought-to easily twist-over that mashed section of shaft-threads to reach the further-inward remaining full-threads, and quite possibly get a sufficient-enough grasp on those still good shaft-threads to at-least adequately perform it's torque-holddown/job (without having-to also grind-down the face of the bevel-gear very much at all).

Hopeful-Cheers,

DCT-Bob

" I would be grateful if you could supply dimensions for the bushing. "

____ I've been delaying my response whilst trying to find anything I've had related to this, but have-to give-up further searching. _ Still, it shouldn't be any problem to figure-out the dimensions...

While my actual lathe-work was always done in thousandths of an inch, (of which the particular dimension-figures are no-longer memorized by me),, I'm now assuming that the metric-dimensions of the stock bushing we are in reference-to, is either 16-id x 20-od x 12mm, or 15-id x 18-od x 10mm. _ However my nearly 4-decade old memory seems to recall that bushing as rather being 15-id x 20-od x 10mm, so I really need a mind-refresher to get all the actual details to come-back to me (without finding any of my old related stuff). _ So if you could confirm the actual size of your (busted)/original bushing as well as the dimensions of the thrust-washer, that would then allow me to figure-out the actual required dimensions of the special-bushing.

__ Anyhow,, my special-bushing had the same general dimensions as stock, except for the extra added-on dimensions of the included 'rim-lip'.

The first special-bushing examples I made in the late-60s had their rim-lip dimensions done with thickness & OD sizes that were slightly smaller than that of the stock thrust-washer (which was intended to be replaced with a thin bevel-shim -[either a .1mm #0400.29.124 or a .2mm #0400.29.125]).

However after having come-across more badly busted case-bosses (like yours) by the mid-70s,, my later bushing-examples were rather made with the reasoning that the function of a thrust-washer wasn't really needed, and-so their rim-lip dimensions were increased to the full-thickness of the stock thrust-washer along-with a slightly larger OD.

Which of those special-bushing versions you pick to choose for your project, will depend on whether you bother to rebuild your busted case-boss or not.

" coupled with a rebuild of the boss. "

____ If you choose to make your replacement bushing with the larger/thrust-washerless rim-lip spec/version, then rebuilding of the boss ought-not really be required. _ Since the normal kick-starting process doesn't overstress that busted area of the case-boss, (as it had gotten busted rather by a severe 'kick-back').

__ After having installed any special-bushing, I've never afterward happened to have ever found one busted or even cracked,, but that's not to imply such is impossible, (as I did once later find one of my early-versions slightly ovalized). _ So you may wish to consider making your modified-bushing out-of something stronger than a brass-alloy, (if you don't rebuild your case-boss).

I once made one special-bushing example out-of a rather strong alloy of steel, and-but never installed it for over a decade after,, but it finally got installed into a Sebring-motor with an extra-damaged boss like yours, (however I've never seen it again).

" Will keep my eyes open for a WC 350 piston, if I'm unable to find a NC piston.

I'm also considering purchasing a new piston... any thoughts on suppliers... "

____ If your con.rod bushing also shows need for attention, it could be reamed-out about 41-thousandths to accept the pin of a BSA-441 piston, which I-think come with a minimum bore-size of 3.105" -(about 78.9mm), which takes the 350-cyl.sleeve out to near it's max.bore-size.

(Just mentioning this in-case you can't source a Ducati-piston any cheaper and have both of the two problems to solve.)

__ UPDATE - While checking to see if the BSA-pistons are still commonly listed on eBay, I then found that a used 350-piston was also listed... http://www.ebay.com/itm/AE-Piston-for-D ... 50&vxp=mtr

You might-not find another std.sized good one available for under a 100-bucks again.

" I will have the the thread cleaned up, and the bevel gear ground down. "

____ After having the stripped/mashed-over metal carefully cleaned-out from the valleys of the original thread-grooving,, then a new L.hand-nut ought-to easily twist-over that mashed section of shaft-threads to reach the further-inward remaining full-threads, and quite possibly get a sufficient-enough grasp on those still good shaft-threads to at-least adequately perform it's torque-holddown/job (without having-to also grind-down the face of the bevel-gear very much at all).

Hopeful-Cheers,

DCT-Bob

PLEASE NOTE... If this-post is not-yet signed-off with '-Bob', then I'm still in the process of completing it,, and if not also included with 'DCT' near bottom as well, then I may edit this post's wording at a later time. - Dct.Bob

-

Nick

- Posts: 246

- Joined: Sat Jun 01, 2013 4:57 pm

- Location: Paradise

Re: Not a good weekend... 350 NC dis-assembly

Piston: Call Venolia or other piston maker and see if they offer the Sebring piston. They still sell old Triumph/BSA pistons.

Or, call them and enquire re the price of duplicating your current piston. Just mail them the original and tell them to duplicate it.They can probably do that, and you'll end up with a nice, modern piston with modern rings, etc. They can probably even make you low-friction slipper piston.

I've been using Venolias in my Triumph and BSA and am very happy with them. Might be a good idea to also ask what grade of honing stone will best suit their rings. I sent my cylinders to Bore Tech in Ohio for their special carbon coating and plateau honing. They can also check that the bore is perpendicular to the cylinder mating surface.

Or, call them and enquire re the price of duplicating your current piston. Just mail them the original and tell them to duplicate it.They can probably do that, and you'll end up with a nice, modern piston with modern rings, etc. They can probably even make you low-friction slipper piston.

I've been using Venolias in my Triumph and BSA and am very happy with them. Might be a good idea to also ask what grade of honing stone will best suit their rings. I sent my cylinders to Bore Tech in Ohio for their special carbon coating and plateau honing. They can also check that the bore is perpendicular to the cylinder mating surface.

Put a Mikuni on it!

-

SebringMike

- Posts: 37

- Joined: Sun Nov 02, 2014 5:43 pm

Re: Not a good weekend... 350 NC dis-assembly

Nick,

Will contact Venolia and a few others before I make my final decision on the piston. This will be affected by the measurement of the piston and cylinder that I will have this week (I don't have high enough quality micrometers to measure either, so I've taken them to a good motorcycle mechanic to measure).

Bob,

The current damaged bushing is 15.3mm ID x 17.9mm OD x 12.3mm long. The ks shaft is 14.9mm OD. I haven't measured the ID of the boss, but is likely in the order of 18mm+ because the bushing basically fell out. So I will need to have a bushing made with and OD of 18mm+ (TBD), ID of 14.9mm and a length of 12.3mm.

The thrust washer is 0.5mm thick, so I would make the "lip" on the bushing 0.5mm thick x ?? OD (estimated at 25mm).

All of these dimensions would of course be confirmed prior to making the bushing.

Two other starter related questions;

a) is the "improved" started gear spring retrofit assembly (that replaces the leaf spring(s)) still available from anybody?

b) the pedal return spring is completely missing from this bike. Can someone provide a photo of the spring installed so I know how it's supposed to look?

Thanks,

Mike

Will contact Venolia and a few others before I make my final decision on the piston. This will be affected by the measurement of the piston and cylinder that I will have this week (I don't have high enough quality micrometers to measure either, so I've taken them to a good motorcycle mechanic to measure).

Bob,

The current damaged bushing is 15.3mm ID x 17.9mm OD x 12.3mm long. The ks shaft is 14.9mm OD. I haven't measured the ID of the boss, but is likely in the order of 18mm+ because the bushing basically fell out. So I will need to have a bushing made with and OD of 18mm+ (TBD), ID of 14.9mm and a length of 12.3mm.

The thrust washer is 0.5mm thick, so I would make the "lip" on the bushing 0.5mm thick x ?? OD (estimated at 25mm).

All of these dimensions would of course be confirmed prior to making the bushing.

Two other starter related questions;

a) is the "improved" started gear spring retrofit assembly (that replaces the leaf spring(s)) still available from anybody?

b) the pedal return spring is completely missing from this bike. Can someone provide a photo of the spring installed so I know how it's supposed to look?

Thanks,

Mike

2004 BMW R1100S, 1986 Kawasaki ZX750R, 1982 Piaggio PX125E, 1979 Ducati Regolarita

1971 Kawasaki H1A, 1970 Yamaha XS1, 1970 Yamaha R5, 1969 Honda CB750K0

1965 Ducati Sebring

1971 Kawasaki H1A, 1970 Yamaha XS1, 1970 Yamaha R5, 1969 Honda CB750K0

1965 Ducati Sebring

-

Eldert

- Posts: 824

- Joined: Sun Nov 01, 2009 3:23 pm

- Location: Hazerswoude Rijndijk Netherlands

Re: Not a good weekend... 350 NC dis-assembly

Hi Mike

Rich Lambrechts from Desmopro used to sell the improved kickstart spring kits

here a pic of a original improved spring and the return spring

Eldert

Rich Lambrechts from Desmopro used to sell the improved kickstart spring kits

here a pic of a original improved spring and the return spring

Eldert

-

DewCatTea-Bob

- Posts: 2897

- Joined: Sun Nov 01, 2009 10:53 am

- Location: Near SE side of Lake Michigan

Re: Not a good weekend... 350 NC dis-assembly

[quote= SebringMike ...

" The current damaged bushing is 15.3mm ID x 17.9mm OD x 12.3mm long. "

____ Thanks for your measurement-readings Mike, although none of your stated figures (nor their equivalent inch-dimensions of .6024-ID; .7047-OD; .4843-L) ring any bells for me I'm afraid. _ So I guess I could accept that the stock bushing dimensions are supposed to be 15x18x12mm.

__ Anyhow,, because tenths of a mm are too large and hundredths of a mm are too small, I've thus always preferred working rather with thousandths of an inch instead. _ So here follows the inch-dimensions for my special-bushing, (listed as seen from outside-to-inside of the motor-case)...

ID = .600" for .150-L / .598-ID for remaining-length;

OD = 1." for .025-L / .715" for .435-L / .710" for .050-L

____ Now to explain all those varied dimensions...

__ The outward/opening-end of the bush-ID is rather .002" larger so that (in the event of a serious kick-back) the pressure is thus-then relieved-away from being as concentrated*directly-over the outer-edge of the boss-opening's casing-rim/hole-lip -(specifically that area-section of the case-boss which has been busted-off), (* conversely, as would otherwise occur with a std.bush's normally non-tapered ID). _ So the .600" opening-ID tapers-down to the .598" ID by .150" inward-length, and the main-length* of the .598" ID remains straight/flat all the way to it's other-end, (* slightly over 9mm long). _ This near-4mm.long taper is recommended for stronger than brass bushings, (as softer bushings probably ought have a greater than .002" dia.taper in order for the expected functional-intent to remain effective, [thus for brass, rather .595" in place of the .598"]).

__ Next concerning the special-bushing's OD...

It's .710" OD inward-nose/end is tapered for a .050" length (till it's main-OD of .715"), so as to help facilitate straight-insertion of the press-fit into the case-boss.

The .715" is a dia.size that should assure a good pressed-fit into the boss-hole.

(Those two suggested OD.sizes might possibly end-up better-off with some slight adjustment of a couple thousandths in either direction, depending-on the actual worn-size of the boss-hole.)

The OD of the rim-lip is-not so important,, but naturally the larger it's diameter, the stronger it should hold-up against a strong kick-back incident.

For the thrust-washerless versions, I'd just leave the 1-inch stock-length un-lathed.

__ The overall-length of the finished bushing is very-near 13mm-long.

However if you prefer that your std.brass-alloy bushing's rim-lip be substantially even thicker (than the thickness of the thrust-washer), then you could possibly make the rim-lip as thick as 1.5mm, providing that you cut-down the length of the ks.shaft's spacer-sleeve by near-around 1mm (or so, to also still allow employment of a thin thrust-washer as well).

(I had chosen to go that more extensive route once, on the only 5-speed motor-case I ever came-across that had it's case-boss busted a bit worse than yours.)

" I haven't measured the ID of the boss, but is likely in the order of 18mm+ because the bushing basically fell out. "

____ That's fairly common, as in a number of cases I've found the stock/lip-less bushing had become partially worked-into the inside where it had then gotten partially ground-away by 1st.gear !

__ Besides the original/stock dimensions, Ducati also offered an over-sized version (which was almost-always certainly required once the original-bushing was found to've become looser-fitting than adequate),, and while the OS.bush would of-course fit more snugly, it too could also possibly relatively-easily fit into the boss-hole with less fitment-pressure than ought be expected, (as it also [as well as the std.bush-size] could often be simply pressed-in with mere thumb/finger-pressure). _ But of-course that poor fitment issue wasn't always found to be the case, and the OS.bush would accordingly require being rather press-inserted with expected care & pressure.

" So I will need to have a bushing made with and OD of 18mm+ (TBD), ID of 14.9mm and a length of 12.3mm. "

____ Yes but, a straight ID of "14.9" is too small and would tend to lead to ks.shaft pressure trying to twist the bushing (within the case-boss) during kick-starting, and-so ought have near-around .010" cold-clearance, (not to mention that the ks.shaft-tip wouldn't fit such a tight hole once the bushing has been pressed into & compressed somewhat within the case-boss),, and, the exact-length is relatively unimportant (in comparison to the dia.dimensions).

And I sure wouldn't count on having just one example made, as most certainly your first-example will likely leave you with better fitment desires ! _ And that's because ya pretty-much need to try-out actually fitting your best-guessed (calculated to fit) example, in order to learn (and likely then find-out for-sure) whether it's OD does (or doesn't) actually perfectly fit within the case-boss as had-been expected.

" The thrust washer is 0.5mm thick, so I would make the "lip" on the bushing 0.5mm thick x ?? OD (estimated at 25mm). "

____ The thrust-washerless rim-lip dimensions themselves are closer to .6mm,, while it's OD need-not be exact, so long as it near-approximates that of the thrust-washer.

" All of these dimensions would of course be confirmed prior to making the bushing. "

____ As I've indicated,, it's rather difficult to 'confirm' the actual best required dimensions until after you've already tried-out your best-guess example to discover what's actually perfect. _ Cuz when ya go to install what ya had expected would be your properly fitting bush,, it seems most-often to turn-out being either a little too small or-else a little too large, (unless ya're just lucky [or don't much give a $#!+ and just go-ahead & use it as-is] ).

).

____ When you finally have a perfect-sized special-bushing,, then it's a rather involved task to get it carefully installed !

I'll advise on the related details after you've gotten further along with the project.

__ Please ask any questions you may now have developed, and let me know how your related intended plans are coming-along so-far at this point, (such as what material you expect/prefer to use for your special-bush).

Hopeful-Cheers,

D.Bob

" The current damaged bushing is 15.3mm ID x 17.9mm OD x 12.3mm long. "

____ Thanks for your measurement-readings Mike, although none of your stated figures (nor their equivalent inch-dimensions of .6024-ID; .7047-OD; .4843-L) ring any bells for me I'm afraid. _ So I guess I could accept that the stock bushing dimensions are supposed to be 15x18x12mm.

__ Anyhow,, because tenths of a mm are too large and hundredths of a mm are too small, I've thus always preferred working rather with thousandths of an inch instead. _ So here follows the inch-dimensions for my special-bushing, (listed as seen from outside-to-inside of the motor-case)...

ID = .600" for .150-L / .598-ID for remaining-length;

OD = 1." for .025-L / .715" for .435-L / .710" for .050-L

____ Now to explain all those varied dimensions...

__ The outward/opening-end of the bush-ID is rather .002" larger so that (in the event of a serious kick-back) the pressure is thus-then relieved-away from being as concentrated*directly-over the outer-edge of the boss-opening's casing-rim/hole-lip -(specifically that area-section of the case-boss which has been busted-off), (* conversely, as would otherwise occur with a std.bush's normally non-tapered ID). _ So the .600" opening-ID tapers-down to the .598" ID by .150" inward-length, and the main-length* of the .598" ID remains straight/flat all the way to it's other-end, (* slightly over 9mm long). _ This near-4mm.long taper is recommended for stronger than brass bushings, (as softer bushings probably ought have a greater than .002" dia.taper in order for the expected functional-intent to remain effective, [thus for brass, rather .595" in place of the .598"]).

__ Next concerning the special-bushing's OD...

It's .710" OD inward-nose/end is tapered for a .050" length (till it's main-OD of .715"), so as to help facilitate straight-insertion of the press-fit into the case-boss.

The .715" is a dia.size that should assure a good pressed-fit into the boss-hole.

(Those two suggested OD.sizes might possibly end-up better-off with some slight adjustment of a couple thousandths in either direction, depending-on the actual worn-size of the boss-hole.)

The OD of the rim-lip is-not so important,, but naturally the larger it's diameter, the stronger it should hold-up against a strong kick-back incident.

For the thrust-washerless versions, I'd just leave the 1-inch stock-length un-lathed.

__ The overall-length of the finished bushing is very-near 13mm-long.

However if you prefer that your std.brass-alloy bushing's rim-lip be substantially even thicker (than the thickness of the thrust-washer), then you could possibly make the rim-lip as thick as 1.5mm, providing that you cut-down the length of the ks.shaft's spacer-sleeve by near-around 1mm (or so, to also still allow employment of a thin thrust-washer as well).

(I had chosen to go that more extensive route once, on the only 5-speed motor-case I ever came-across that had it's case-boss busted a bit worse than yours.)

" I haven't measured the ID of the boss, but is likely in the order of 18mm+ because the bushing basically fell out. "

____ That's fairly common, as in a number of cases I've found the stock/lip-less bushing had become partially worked-into the inside where it had then gotten partially ground-away by 1st.gear !

__ Besides the original/stock dimensions, Ducati also offered an over-sized version (which was almost-always certainly required once the original-bushing was found to've become looser-fitting than adequate),, and while the OS.bush would of-course fit more snugly, it too could also possibly relatively-easily fit into the boss-hole with less fitment-pressure than ought be expected, (as it also [as well as the std.bush-size] could often be simply pressed-in with mere thumb/finger-pressure). _ But of-course that poor fitment issue wasn't always found to be the case, and the OS.bush would accordingly require being rather press-inserted with expected care & pressure.

" So I will need to have a bushing made with and OD of 18mm+ (TBD), ID of 14.9mm and a length of 12.3mm. "

____ Yes but, a straight ID of "14.9" is too small and would tend to lead to ks.shaft pressure trying to twist the bushing (within the case-boss) during kick-starting, and-so ought have near-around .010" cold-clearance, (not to mention that the ks.shaft-tip wouldn't fit such a tight hole once the bushing has been pressed into & compressed somewhat within the case-boss),, and, the exact-length is relatively unimportant (in comparison to the dia.dimensions).

And I sure wouldn't count on having just one example made, as most certainly your first-example will likely leave you with better fitment desires ! _ And that's because ya pretty-much need to try-out actually fitting your best-guessed (calculated to fit) example, in order to learn (and likely then find-out for-sure) whether it's OD does (or doesn't) actually perfectly fit within the case-boss as had-been expected.

" The thrust washer is 0.5mm thick, so I would make the "lip" on the bushing 0.5mm thick x ?? OD (estimated at 25mm). "

____ The thrust-washerless rim-lip dimensions themselves are closer to .6mm,, while it's OD need-not be exact, so long as it near-approximates that of the thrust-washer.

" All of these dimensions would of course be confirmed prior to making the bushing. "

____ As I've indicated,, it's rather difficult to 'confirm' the actual best required dimensions until after you've already tried-out your best-guess example to discover what's actually perfect. _ Cuz when ya go to install what ya had expected would be your properly fitting bush,, it seems most-often to turn-out being either a little too small or-else a little too large, (unless ya're just lucky [or don't much give a $#!+ and just go-ahead & use it as-is]

____ When you finally have a perfect-sized special-bushing,, then it's a rather involved task to get it carefully installed !

I'll advise on the related details after you've gotten further along with the project.

__ Please ask any questions you may now have developed, and let me know how your related intended plans are coming-along so-far at this point, (such as what material you expect/prefer to use for your special-bush).

Hopeful-Cheers,

D.Bob

You do not have the required permissions to view the files attached to this post.

PLEASE NOTE... If this-post is not-yet signed-off with '-Bob', then I'm still in the process of completing it,, and if not also included with 'DCT' near bottom as well, then I may edit this post's wording at a later time. - Dct.Bob

-

DewCatTea-Bob

- Posts: 2897

- Joined: Sun Nov 01, 2009 10:53 am

- Location: Near SE side of Lake Michigan

Re: Not a good weekend... 350 NC dis-assembly

From viewtopic.php?f=3&t=2059#p15407

" new piston purchased. "

____ So exactly what did you find for a replacement piston ?

" I'm waiting on the new bushing for the kick-starter to be made. "

____ So exactly which dimensions did you end-up choosing to settle on, for that ?

And what is your latest thinking on whether you'll still bother with trying to weld-up & re-machine the busted rim-boss of the ks.bushing-hole in the case, before attempting to fit your new ks.bushing ?

____ Back when this thread was still active, I then still had more related info to finish submitting for your consideration (concerning this ks.bearing repair-job),, but now at this over-extended later time, I'll be lucky to be able to recall even just one-third of it all.

Hopeful-Cheers,

-Bob

SebringMike wrote:The tear-down is 100% complete. The cylinder was honed and the new piston purchased. All new bearings are on order and seals & gaskets are in hand. I'm waiting on the new bushing for the kick-starter to be made.

" new piston purchased. "

____ So exactly what did you find for a replacement piston ?

" I'm waiting on the new bushing for the kick-starter to be made. "

____ So exactly which dimensions did you end-up choosing to settle on, for that ?

And what is your latest thinking on whether you'll still bother with trying to weld-up & re-machine the busted rim-boss of the ks.bushing-hole in the case, before attempting to fit your new ks.bushing ?

____ Back when this thread was still active, I then still had more related info to finish submitting for your consideration (concerning this ks.bearing repair-job),, but now at this over-extended later time, I'll be lucky to be able to recall even just one-third of it all.

Hopeful-Cheers,

-Bob

PLEASE NOTE... If this-post is not-yet signed-off with '-Bob', then I'm still in the process of completing it,, and if not also included with 'DCT' near bottom as well, then I may edit this post's wording at a later time. - Dct.Bob

-

SebringMike

- Posts: 37

- Joined: Sun Nov 02, 2014 5:43 pm

Re: Not a good weekend... 350 NC dis-assembly

Bob,

I purchased a 76.5mm Omega piston from Nigel.

I provided the machinist the dimensions you suggested, and I'm waiting for him to respond regarding his ability to meet those dimensions.

I also have a new normal bushing (without the flange) as a backup.

I had the kickstarter boss TIG welded, while I was having other work done. While it may not have been mechanically necessary, it also didn't cost much in time and effort to have it cosmetically repaired.

Mike

I purchased a 76.5mm Omega piston from Nigel.

I provided the machinist the dimensions you suggested, and I'm waiting for him to respond regarding his ability to meet those dimensions.

I also have a new normal bushing (without the flange) as a backup.

I had the kickstarter boss TIG welded, while I was having other work done. While it may not have been mechanically necessary, it also didn't cost much in time and effort to have it cosmetically repaired.

Mike

2004 BMW R1100S, 1986 Kawasaki ZX750R, 1982 Piaggio PX125E, 1979 Ducati Regolarita

1971 Kawasaki H1A, 1970 Yamaha XS1, 1970 Yamaha R5, 1969 Honda CB750K0

1965 Ducati Sebring

1971 Kawasaki H1A, 1970 Yamaha XS1, 1970 Yamaha R5, 1969 Honda CB750K0

1965 Ducati Sebring

Return to “Ducati Singles Main Discussions (& How to Join)”

Who is online

Users browsing this forum: No registered users and 139 guests